Lighting up the light energy: Photovoltaic light-guiding film – the invisible engine of the solar energy revolution

Abstract: Due to reflection loss and limited optical path, a large amount of light energy is not effectively utilized in traditional solar cells. Photovoltaic light-guiding film, with its high light-transmitting substrate and precise microstructure, breaks through the bottleneck: it greatly reduces reflection, guides light to pass through the battery, significantly extends the optical path and increases the absorption probability. This seemingly thin innovative layer is becoming the key to unlocking higher photovoltaic efficiency and reducing the cost of electricity, paving the way for the deep penetration of the solar energy industry.

In the human pursuit of clean energy, solar energy is undoubtedly one of the most promising stars. However, traditional crystalline silicon photovoltaic cells face a fundamental challenge: A large amount of precious sunlight is not effectively captured. According to research by the National Renewable Energy Laboratory (NREL) of the United States, the surface reflection loss of standard photovoltaic modules can reach an astonishing 4%-10%, and some light escapes after just “brushing by” the battery material, so the overall light absorption efficiency is far from the theoretical limit.

It is in this context that the innovative material PV Light Guiding Film has emerged like the light of dawn. It does not directly participate in the photoelectric conversion, but like a shrewd “light guide”, it optimizes the journey of light in the battery through a unique physical structure, thereby doubling the energy capture efficiency.

1. Breaking through the reflection bottleneck: high-transmittance substrate, maximizing energy entrance

The core foundation of the light guiding film is a polymer substrate with extremely high optical transparency. Its primary task is to minimize the initial reflection loss of the incident light in the outermost layer of the component. Compared with ordinary glass or traditional packaging materials, the transmittance of high-quality light guiding film in the visible and near-infrared spectral regions (the main energy region of solar radiation) can easily be >94% (Fraunhofer ISE research report). This ensures that most of the sunlight can enter the battery unimpeded, laying the foundation for subsequent efficient utilization.

Authoritative link reference: Fraunhofer Institute for Solar Energy Systems (ISE) – Optical Materials Characterization

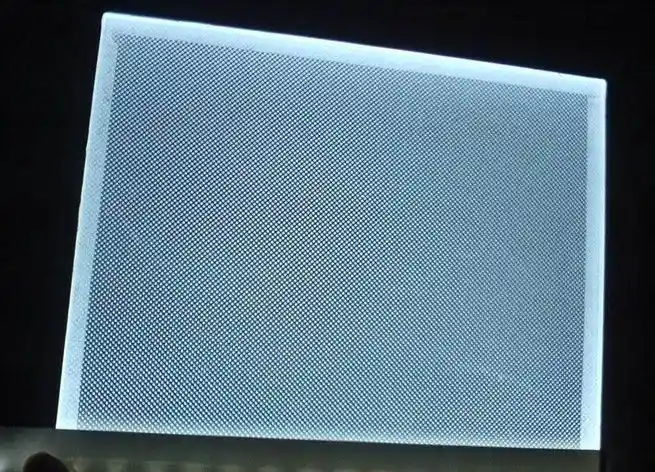

2. Driving the path of light: microstructure refraction, turning straight behavior into wandering

The real magic of light-guiding film lies in the micro/nanoscale structures (such as prism arrays, microlenses, diffraction gratings, etc.) carefully designed on its surface or inside. When light reaches these structures, it does not penetrate in a straight line, but is controllably deflected according to Snell’s refraction law. This design cleverly “guides” the light that might have been lost by “straightly passing through” the active layer of the battery to a more inclined or even lateral propagation path. Just like letting the light “take a few more turns” inside the photovoltaic material, the optical path length is significantly extended.

Authoritative link reference: Principles of Optics by Max Born & Emil Wolf – Fundamental Refraction Laws

3. Stimulate total internal reflection: light trapping effect, create photon cage

After the light refracted by the microstructure enters the photovoltaic material (such as silicon wafer), its propagation angle increases, greatly increasing the probability of total internal reflection (TIR) with the upper and lower surfaces of the battery. Once the incident angle is greater than the critical angle, the light will be completely reflected back into the battery instead of escaping. This forms an efficient “light trapping effect” (Light Trapping), where photons bounce repeatedly in a carefully designed “optical cage”, and each bounce increases the precious chance of being absorbed by the semiconductor material and exciting electrons. Studies have shown that effective light trapping can “equivalently thicken” the effective light absorption layer of thin-film batteries by several times (ScienceDirect related review).

Authoritative link reference: ScienceDirect – Light Trapping in Solar Cells: A Review

4. Master of Spectral Management: Adjustable Structure, Matching Absorption Characteristics

The shape, period, depth and other parameters of the light-guiding film microstructure can be precisely designed. This gives it another key capability: spectral management. By optimizing the structure, the absorption characteristics of specific photovoltaic materials (such as crystalline silicon is sensitive to infrared light and perovskite is efficient for visible light) can be targeted to prioritize the photon guiding efficiency in its weak absorption band. For example, designing a specific grating can enhance the scattering of long-wavelength (low-energy) infrared to compensate for the insufficient absorption of crystalline silicon in this area (Optics Express related research). This ability to “distribute” photons on demand makes the overall spectral response of the cell more balanced and more efficient.

Authoritative link reference: Optics Express – Tailoring light trapping for silicon solar cells

5. Compatibility and universality: empowering various photovoltaic technologies

The charm of light-guiding film lies in its technical neutrality and strong compatibility. It can be applied to:

- Crystalline silicon cells (mainstream): As an additional layer on the encapsulation glass or integrated into the backplane, it significantly improves efficiency.

- Thin-film cells (such as CIGS, CdTe): Because of their thin active layer, the light path extension effect brought by the light-guiding film is particularly significant, which is the key to breaking through the efficiency ceiling.

- Emerging cells (perovskite, stacked cells): As an efficient light management component, it optimizes the photon distribution of each sub-cell. This wide applicability makes it a universal tool for improving the efficiency of existing production line components and next-generation photovoltaic technologies.

Industry application reference: PV Tech – Light management films gaining traction in solar module market

6. Leverage for cost reduction and efficiency improvement: Economic efficiency drives scale-up

The core value of light-guiding film is ultimately reflected in the reduction of system levelized cost of electricity (LCOE). Although it adds a layer of material cost, the module power increase (generally reported gains are 3%-10%) it brings means significant increase in power generation under the same installation area. In large power stations, this directly dilutes balance of system (BOS) costs such as land, brackets, wiring, and installation**. The International Energy Agency (IEA) report emphasizes that continuously improving conversion efficiency is one of the most effective ways to reduce photovoltaic LCOE. As a relatively mature and easy-to-integrate efficiency-enhancing technology, light-guiding film has an extremely attractive input-output ratio and is accelerating the commercialization process.

Authoritative link reference: International Energy Agency (IEA) – Trends in Photovoltaic Applications

Photovoltaic light-guiding film is not a disruptive new material, but a masterpiece of exquisite optical engineering design. It does not change the properties of the photovoltaic material itself, but fundamentally optimizes the core process of light energy input into the battery and being absorbed. By reducing reflection loss, extending the optical path, stimulating light trapping, and managing the spectrum, it efficiently converts photons that were once “unseen” or “uncaptured” into current that drives the world.

With the continuous advancement of micro-nano processing technology and the cost reduction brought about by large-scale production, light-guiding film is moving from precision devices in the laboratory to the vast photovoltaic field. It is like a silent guide, silently leading every ray of sunlight to the most efficient destination on each solar panel. When the trickle of efficiency improvement converges into a river, photovoltaic light-guiding film, as the “invisible engine” in this solar revolution, will eventually drive the wave of clean energy to sweep the future of human civilization more violently.