Key Steps in Backlight Guide Technology

1) Design & Specification:

This initial stage involves defining the back-light’s purpose, size, required brightness, and compatibility with the target application (LCD, TV, etc.). Engineers may utilize computer-aided design (CAD) software to create a detailed blueprint.

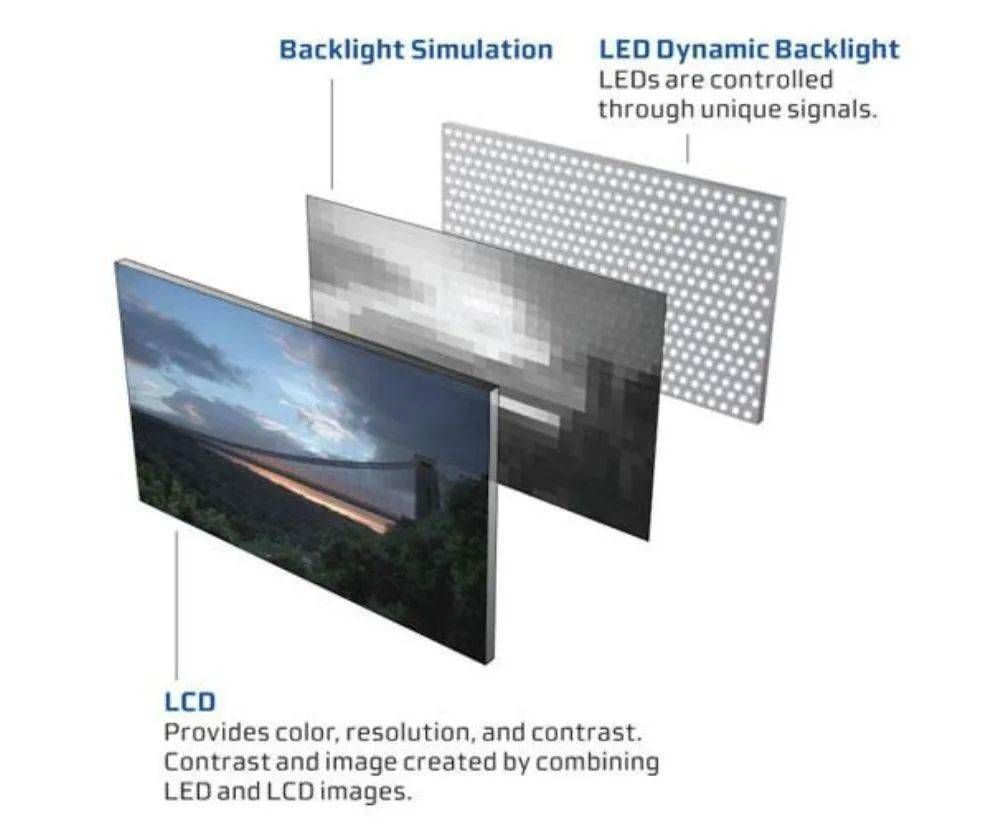

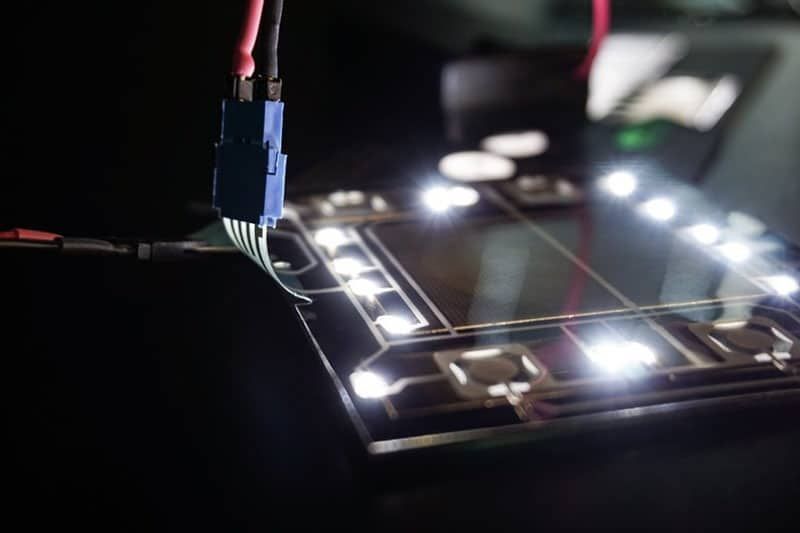

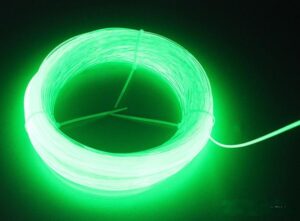

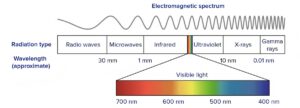

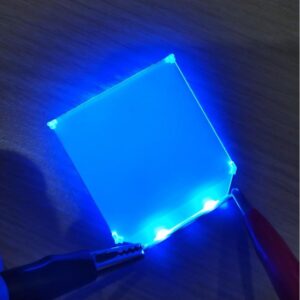

2)Light Source Selection:

Depending on the design, engineers choose the most suitable light source. Common options include LEDs (light-emitting diodes) for energy efficiency and CCFLs (cold cathode fluorescent lamps) for specific applications.

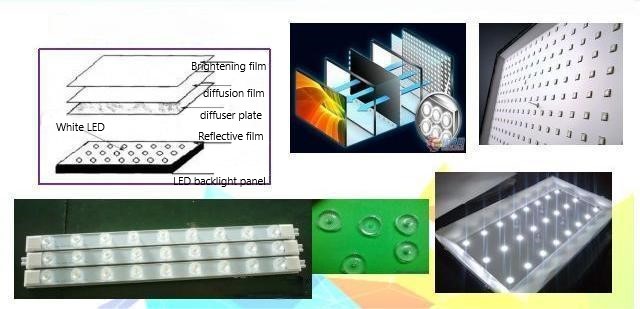

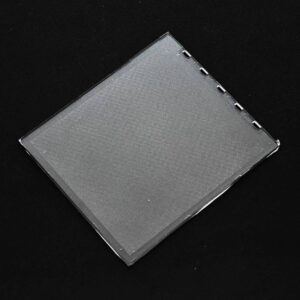

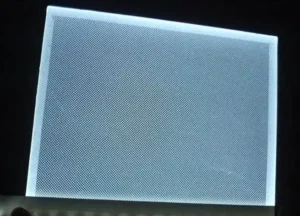

3)Light Guide Panel (LGP) Fabrication:

The LGP is a transparent panel that distributes light from the source uniformly across the back-light. This stage involves shaping and treating the LGP material (often acrylic) to achieve the desired light distribution pattern.

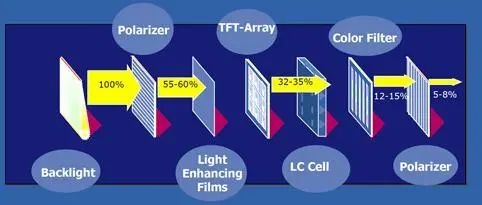

4)Backlight Assembly:

Here, all components are meticulously assembled. The light source is positioned strategically, and the LGP is integrated with diffusers or reflectors to optimize light distribution and minimize glare.

5)Testing & Quality Control:

The final stage involves rigorous testing to ensure the backlight meets all performance specifications, including brightness uniformity, color accuracy, and energy efficiency. Units that fail inspection may undergo adjustments or be discarded.

GET A FREE QUOTE